Cold Extrusion Process: Best Guide 2023

On June 7, 2023 by rimrockExtrusion technology has been for a long time, especially in the metal manufacturing industry. The forming process includes forcing a workpiece through a die to form the desired. The process is easy to work with as it does not require a lot of machinery and equipment to work with.

But what does the cold extrusion process look like? Well, there are a few things required for this process to be operational. That’s what we are going to look at in this article. Check out the following:

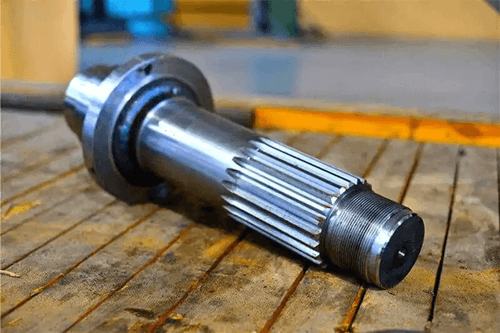

Cold Extrusion Process

The cold extrusion process requires a machine that will push the billet and the die it to work. Therefore, three things are essential for this forging process to work. The pushing machine, the material to be deformed, and the die.

The hydraulic press is the machine that is usually used to create the force. However, other manufacturers have been improving other ways to create this force with the likes of motor-driven couplers. However, what is important is to ensure that you have gotten enough pushing pressure.

The next is the die that gives the pushed biller the desired shape. Dies are formed independently, and in most cases, they are made from metals that are harder from the material being formed. This helps them to withstand the pressure that the workpiece is exposed to.

The cold extrusion process does not require the heating of the billets. The metal is forged at room temperature, which makes it easy and cheaper to produce forgings.

Benefits Of Cold Extrusion

There are many advantages that come with cold extrusion, and one of them is cheaper products. Because of the lack of heating of the billets, a lot of cost is saved, which most manufacturers then transfer to customers. Therefore, cold extrusion products are cheaper.

The cold extrusion process is also ideal for mass production. These are benefits that make this metal-forming process popular.

Cold extrusion and cold forging are almost the same, but the latter uses punching to form the parts. Visit https://www.coldforgingchina.com/ for more about this technology.

Leave a Reply