Why Hot Die Forging? Here Are 5 Advantages You Should Know

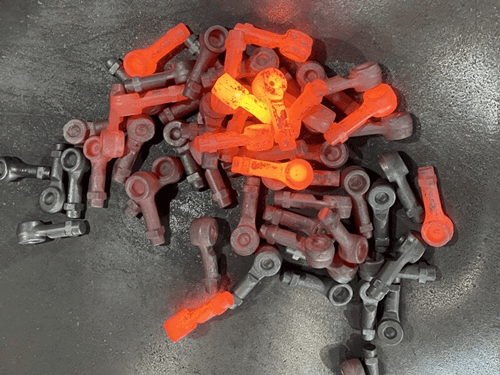

On August 7, 2023 by rimrockHot die forging involves heating a metal workpiece to high temperatures and then using a hammer or a press to shape it into a predefined design. The heated metal, softened by the high temperatures, can be manipulated easily, reducing the force needed for deformation.

This article will highlight five key advantages of hot die forging that machine users should be aware of.

Enhanced Metallurgical Properties

One of the top advantages of hot die forging is the improvement it imparts to the metallurgical properties of the workpiece. The forging process refines the grain structure of the metal, enhancing its overall mechanical properties, such as toughness and fatigue resistance. This means that forged parts are stronger and more reliable, extending the lifespan of the final products in which they are used.

Complex Shapes and Sizes

Hot die forging enables the production of components with complex shapes and sizes that might be difficult or impossible to achieve using other manufacturing methods. The high temperature makes the metal more malleable, allowing the creation of intricate designs with precision. This advantage opens the door for various industrial applications, from automotive to aerospace, where complex and precise parts are crucial.

Cost-Effective Production

When it comes to large-scale manufacturing, hot die forging offers significant cost benefits. Despite the initial investment in die design and fabrication, the long-term cost-effectiveness becomes evident with mass production. The dies can be used repeatedly to produce identical parts, reducing waste and cutting down production costs.

Reduced Need for Finishing Operations

Hot die forging often reduces the need for subsequent finishing operations, such as machining or heat treating. Since the forging process can produce close-to-finished parts with excellent surface finish, the additional costs and time required for extra finishing processes can be significantly minimized.

Improved Production Efficiency

Last but not least, hot die forging machines typically offer high production rates, increasing overall efficiency. The hot forging process allows for rapid shaping and manipulation of metal workpieces. Coupled with the ability to produce identical parts using the same die, this significantly speeds up production times and increases throughput, ultimately leading to greater profitability.

Check out hot die forging for some of the best quality and affordable forgings.

Archives

Calendar

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 | 31 | |||

Leave a Reply